Retrofitting ships with innovative engine and propulsion technologies can help achieve operational efficiencies, and significantly reduce emissions.

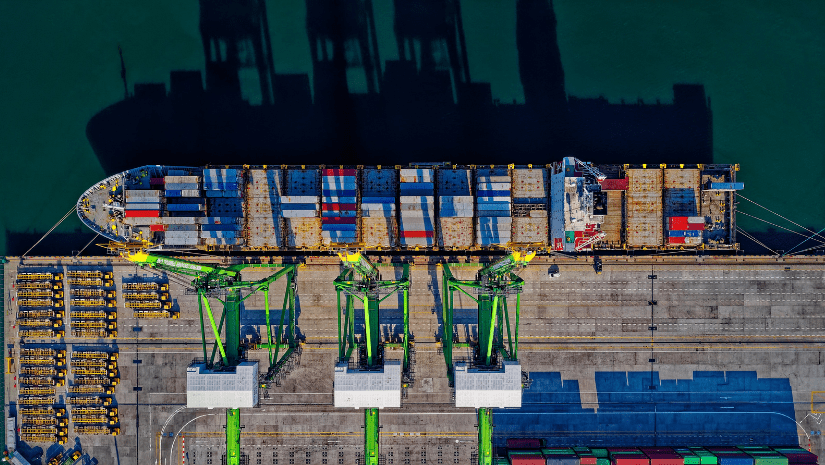

While shipping plays a critical role in the global economy, it is also a large and growing source of pollution. In 2018, global emissions from maritime transport represented 1 076 million tonnes of CO2, and were responsible for around 2.9 % of all emissions caused by human activities. Making shipping more energy-efficient is therefore key to reducing emissions, and to achieving Europe’s climate goals. The EU-funded SeaTech project sought to contribute to these objectives, through applying technological innovation.

Dynamic wings and efficient engines

“There are thousands of ships that use old technologies and run on fossil fuels like diesel,” explains SeaTech project coordinator Anders Öster from Wärtsilä. “We identified two key innovations we thought could address this and help to significantly reduce emissions.” The objective of the project was to combine new ship engine and propulsion innovations, and to demonstrate that these could be retrofitted to make existing vessels more fuel-efficient. The propulsion innovation consists of a dynamic wing, which looks like the fin of a large whale. This is mounted at the ship’s bow, and works by capturing wave energy to produce extra thrust. “We are harvesting energy from the sea, and taking advantage of the power generated when waves go up and down,” adds Öster. “This wing is biomimetic, in that it is inspired by nature. Whales and dolphins use the same phenomena to propel themselves.” The wing can also be used to stabilise the ship in rough weather. The proposed engine innovation meanwhile aims to achieve more control over combustion. It is most efficient running on liquefied natural gas, which is cleaner than diesel. The solution is also designed to reduce emissions of methane gas from ships as much as possible.

Maritime safety: Council and Parliament strike deals to support clean and modern shipping in the EU |

Testing in wave tanks and at sea

The project team wanted to show that these two innovations work best when operating together. For example, when the wing gives the vessel extra push in choppy waters, power from the engine can be reduced, thus achieving fuel efficiencies. “We carried out a lot of testing in wave tanks, and also built a 10-metre-long ship model,” says Öster. “This was tested in the Aegean Sea.” Data was gathered and analysed, to see how the two innovations performed. It was noted that the energy provided by the wing depends a great deal on ship length and wave conditions. The engine innovation was also retrofitted onto a small passenger ferry. Another EU-funded monitoring project, called GREEN RAY, found that methane emissions were lower on board the ferry, and confirmed that the upgraded engine technology has potential to reduce overall emissions.

Transforming maritime transport

Wärtsilä has brought the engine innovation to market, and plans to develop the innovation further for other engine types. “Assuming just 10 % of European short-sea vessels were to be retrofitted in such a way, 32.5 million tons of CO2 would be eliminated annually,” notes Öster. “This is the equivalent of emissions from 200 000 passenger cars.” Next steps for the propulsion system include prototyping and pilot tests. “The wing requires a lot of testing at sea, because there are so many variables to take into account,” says Öster.

Más información: CORDIS

Leave a Reply